Knowledge

How to determine the output required?

The power of a stove is expressed in kW and indicates the amount of useful heat (i.e. heat which actually heats the house) that this stove can produce.

This heat must effectively compensate, as closely as possible, for the heat that the building naturally loses. The power required to heat a room varies depending on outside temperature, the size of the room, which way the property faces, geographical location and the standard of insulation in the building.

A stove that is too small will not be able to heat up (or reheat) the room in cold weather. Alternatively, a stove that is too powerful will often work at a low rate in conditions that are not very beneficial. Sometimes it will overheat the room even at a lower rate. Choosing a 20 kW stove where a 10 kW model would be sufficient would be a very bad decision.

These various factors mean it is not easy to carry out a simple calculation. You can get an idea from our output calculator however we can discuss this with you in more detail at our site visit. You can filter our products pages by output so refining your search.

Radiation or convection heating?

Did you know that different woodstoves create different types of heating. And they work in very different ways.

Research shows that people are most comfortable in a room where they feel warm up to chest height, but where the air is not too heavy to breathe in.

Most cast iron woodstoves provide radiation heating. The rays of heat will heat people, surfaces and objects in a room, and it works quickly. Radiation heating is ideal for rooms with high ceilings. It creates an even heat where needed, so neither your feet nor your nose need be cold.

The concept of convection heating will draw cold air in under the woodstove, heat it up between double sidewalls and release it on the top. The heat rises to the ceiling and will gradually be “pressed” down. In the beginning your head will feel warmer than your feet. Convection woodstoves are a good choice if you want to place the woodstove near flammable materials or don’t have a firewall behind it.

Source: Jotul

Should I line my chimney?

The chimney is the engine of your stove. If you don’t get your chimney right your stove will not perform as it was intended.

The chimney – or its draught to be more precise – is the most important factor in ensuring your stove works well. The smoke produced by the combustion of the wood – very hot and therefore very light – has a natural propensity to rise.

The flue must allow it to disperse.

What makes a good chimney ?

It must create sufficient but not excessive draught for the stove to which it is connected.

And what is needed to create this draught ?

- sufficient height,

- a chimney that is as vertical and straight as possible,

- a smooth surface that does not prevent the dispersal of smoke,

- an appropriate size in cross section – preferably round rather than square – and never less than the diameter of the stove's smoke outlet,

- a chimney that has a good cover, which ensures a sufficient draught regardless of the direction and speed of the wind. The dimensions of the chimney are determined by your supplier.*

At Ebben & Yorke we strongly advise all our clients to have their chimney lined prior to the appliance being installed by a competent HETAS-approved person.

The benefits of lining the chimney are extensive, and we believe the following advice from Clearview Stoves best sums up why we believe you should line your chimney:

“A chimney is a passage from the place of combustion to the outside world. Warm flue gases should rise through this passage to the point of exit. For a chimney to operate satisfactorily it should be smooth, warm and as straight as possible. If a chimney is irregular and rough, or cold and damp, flue gases will move slowly. Cooler gases will mean inadequate chimney suction and poor flue gas speed.

We always advocate flue lining where possible for the following reasons:

A flue liner will substantially decrease your chimney volume. Consequently, higher temperatures will be maintained and flue gases will travel faster, generating a greater and more consistent draft. When possible, flue liners should be insulated, increasing flue temperature. A warm flue will collect less deposit, cleaning will be much easier and condensation should not occur in the flue. It is possible to clean a lined flue well, leaving the liner almost as clean as new. It is rarely possible to remove all deposits that accumulate in unlined flues as there are always holes and corners a brush does not reach.

The combination of a Clearview clean burning stove and a warm flue liner should mean chimney fires are a thing of the past. Chimney fires are a common and frightening occurrence in an unlined chimney and may cause substantial damage.

A well installed stove should emit no smoke or fumes to the room. If a flue is damp and cold it will produce a poor draft, this poor draft may reduce further during slow burn periods as the flue cools. Chimneys are usually in much better condition externally than internally. Many years of sulphur attack may have eaten half way through brickwork and mortar. Internal feathers dividing one flue from another may have perforated or collapsed allowing flue gas to pass into redundant, uncleaned flues.

Air is also an important consideration to optimum performance of your stove.

The combustion of wood consumes air (8 m³ of air is required to burn 1 kg of wood). In older houses, air gets in under the doors and frames. In modern houses, which are more airtight, an outside air inlet is required. This should be as close to the stove as possible.

Other systems that require a lot of air – such as a cooker hood or ventilation system – which can affect the operation of the stove, must also be taken into account. These could affect the operation of the stove with the risk of the fire going out or backdraughts of smoke into the house.

Sources: Stuv / Clearview Stoves

What if I have no chimney?

If you have no masonry chimney in your property we will supply a twin wall insulated flue. This flue is stainless steel (coloured options now available) and comes with insulation injected between the two walls, reducing the clearances to combustibles to as little as 50mm in some cases.

These chimney systems can pass through the house internally or externally up a wall and now come in matt black as an option. Other RAL colours available as special orders.

What fuels can I use?

Which wood should you use?

Different types of wood have different heat capacities and do not burn in the same way. Generally speaking, you should choose hard wood such as oak, beech, ash, birch, hornbeam or fruit trees. They produce lovely flames and lots of embers, which glow for a long time.

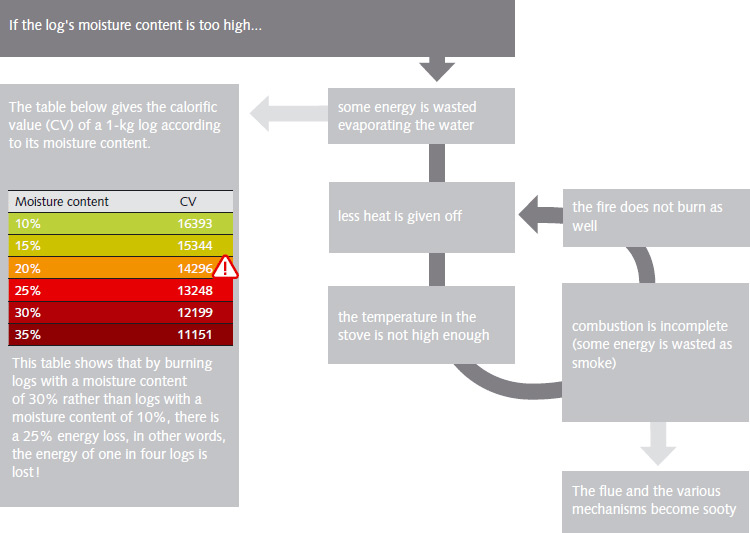

Drying ---- Whatever wood you choose, it should be really dry. Damp wood provides a great deal less heat and a large amount of the energy is used just to evaporate the water it contains. Sapwood - as the soft wood just beneath the bark is called - can contain up to 75 % water. Moist wood also releases a lot of smoke, produces few flames and causes the stove, its glass door and the chimney to get dirty and soot up. Big logs should be chopped up to dry better. Wood should be covered or sheltered from the rain but well ventilated. Generally speaking, you should allow two years for the wood to dry properly. You will soon learn to estimate the dryness of the logs by holding them in your hand. The drier they are, the lighter they will feel and they will produce a clearer sound when you knock them together.

To avoid

Conifers : They produce a lot of heat but burn quickly ; they spit embers and the resins they contain dirty the chimney.

Wood that has been treated chemically, railway sleepers, and chipboard, which soon make appliances and chimneys dirty and can give off toxic fumes.

Wet wood is a big no no. Why?

Source: Stuv

What’s the best way to light a stove?

Start the fire from the top! Correct wood burning is more environmentally friendly, reduces costs and increases fire safety.

Starting the fire from the top provides quicker heating of the burn chamber, which provides proper draft in the flue and pipe quickly, more oxygen to the flames and higher temperature. The flames on the top heats up the logs underneath so that they release the gasses that make the fire burn and keep on burning. Use firelighters to ensure rapid lighting of the kindling wood on top. In this way, you will avoid unnecessary smoke in the kindling phase. Slow kindling and low temperature lead to an increase an increase in airborne dust that is many times multiplied.

How to build a fire – Use logs of dry wood on the bottom and a mix of kindling wood and a couple of firelighters on the top. Finish it off with a large log.

Use dry wood – A rule of thumb is that dry wood is lighter and has deeper cracks. When hitting two logs against each other, it should sound like a bat hitting a ball. If you use wood with a higher moisture content (more than 20%), the emissions of soot and particles will be 10 to 30 times higher than if you use dry wood.

Make sure there is enough air

Make sure there is enough air in the house, so that the woodstove has enough air for the combustion process.

Kitchen fans and ventilation systems that pull air out of the house will reduce the draft in the chimney.

Open up all vents in the woodstove. Feel free to open the door slightly for up to 5 minutes until the fire is burning properly. When the fireplace is warm, after about 15 minutes, the vents can be adjusted again. It is important not to shut the damper (if used) too much, as this will suffocate the flames. The wood should always burn with a visible flame. Fires without flames emit twice as much soot and particles.

Heat Output Calculator

Please Note: the calculation is based on an estimated outside temperature of -1°C. For accurate assessment of heating requirements a full heat loss calculation must be completed before installation of any appliance.